The Slot Cutter is used to square up the walls in potash mines. Its unique cutting head with a 16 foot cutting blade, can spin 360º and fold over to travel through the mine.

Fabrication

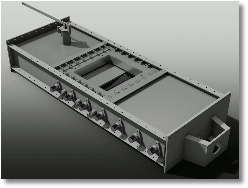

Boiler Boxes – Refurbished

In a hot-job shop you never know what will come through the doors.

Take these worn boxes that attach to the sides of boilers. We needed to reuse some of the components, but build new, stronger frames.

These new Boiler Boxes will fit just like the old ones, but last a lot longer.

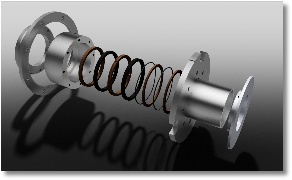

Boiler Face Plate w/Expansion Folds

A boiler gets hot, really hot. And when it does, the walls expand.

To help control expansion, one solution is to cut slots in the walls and weld “Expansion Folds” over top of these slots.

This gives the plate a little more room to expand as the pressure builds in the unit. They are placed around the plate helping it expand as it heats.

Goodman Potash Loader – First Field Test

This is the first field test of the remote controlled potash loader in a coal yard in Ashland, KY.

Goodman Potash Loader

This is the first test of the unit in an actual potash mine in Canada.

Cutting Grooves in a Rope Drum

Our Toshiba BP-150 in action!

Post Ash Loader Project

We Love Big Projects!

One of the most exciting projects we’ve worked on has been the Goodman Industries Radio Controlled Pot Ash Loader.

From design, to welding, electrical, hydraulics and then field testing.

Tested & Trusted

Riggs products are used in all conditions, in all type of facilities and in many different environments.

Still wondering if Riggs can handle your job?

Coal and Coke Facility Repairs

Rebuilds and Overhauls

After years of hard service your equipment will need an overhaul. Riggs will tear down your worn machinery and rebuild it from the ground up.

Using the newest components and most modern techniques, they might run better than they have in years!

Minimal Downtime – Fast Turnaround

Though coal and coke can be hard on your equipment, Riggs’ employees work even harder to get your machinery back on-line and keeping you operating.

Better Components …

A lot has changed since many of these units went into service.

Many components are just made better than the OEMs. Better springs, rings and gaskets mean more reliable equipment.

How Safe Are Your Work Platforms?

How safe do your employees feel working on your old, outdated platforms? Are they still up to code?

Replace those aging, rusted, dangerous platforms with new solid units from Riggs.

Chutes and Hoppers

Getting Your Materials from Point A to B!

Everyone’s Hoppers and Chutes are a bit unique. They have to fit back in place just right. Getting that fit correct is something we know at Riggs.

A new custom replacement for a worn out unit or a rebuilt will fit like a glove. Access doors, cleanouts and manways back where they need to be.

You’ll be happy you chose Riggs.