Preparing for an outage can be almost as stressful as the actual event. Gathering drawings, getting materials ready, prepping vendors, suppliers and employees. Trying your best not to overlook any details.

But often it’s not the big ticket items that slow or even stop production, it could be something as simple as missing shims to get a new pump to the correct height, a missing blind to close off a pipe section before adding a new unit, keys for new shafts or custom bolts you swore you ordered and now will take a week to machine.

I’ve seen all of these, and more. The excuses are varied, who was responsible for ordering the items, I thought they were included with the quote, the existing ones should have worked with the new unit, and even – I just forgot!

So how best to avoid these situations?

– Get current manufacturer drawings for new equipment. Trying to fit a new pump on an old base never works out. Plan for modifications and additions. Make sure everyone has the same version prints. Don’t rely on old drawings someone pulled from the file or had stored on their computer. Verify you are on the same version. If you have to, create a new master set and pass them out to everyone involved.

– Next, and sometimes more importantly, is having a local machine shop who can respond timely, ready for such emergencies. This might require several shops of varied disciplines; one for burn outs, one for custom bolts or nuts, one for blinds and piping…

– You might want to get the shops involved early in the process, rather than late one evening when you realize something has gone wrong. They may make recommendations as to what items you may have overlooked. They may need to stock up on certain materials so you don’t have to wait to have them shipped in (and overnighted at an additional expense).

They may also have to juggle their schedule around to make sure they have the manpower available during the outage. Are they normally closed on weekends? Will they have a method to call someone in for a quick job? Are they in the middle of other shutdowns or production runs?

Some common last minute items:

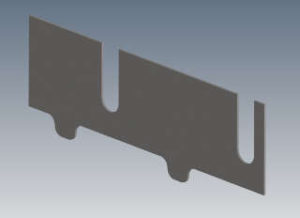

- Blinds (slip/paddle, bleeder and orifice)

- Keys for shafting

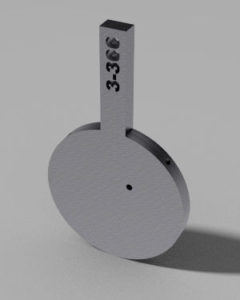

- Shims

- Tube Plugs

- Custom Bolts and Nuts (or just odd sized)

- Non-stock metals (stainless piping or angle, brass bushings)

By failing to prepare, you are preparing to fail. – Benjamin Franklin

Riggs Machine & Fabricating – Serving industry in KY, OH and WV for over 45 years!