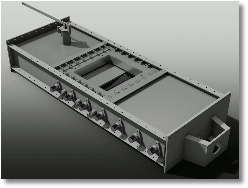

This is the first test of the unit in an actual potash mine in Canada.

Author: RMF

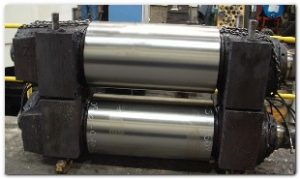

Mazak VCN-700D Drill & Tap

Cutting Grooves in a Rope Drum

Our Toshiba BP-150 in action!

Post Ash Loader Project

We Love Big Projects!

One of the most exciting projects we’ve worked on has been the Goodman Industries Radio Controlled Pot Ash Loader.

From design, to welding, electrical, hydraulics and then field testing.

Tested & Trusted

Riggs products are used in all conditions, in all type of facilities and in many different environments.

Still wondering if Riggs can handle your job?

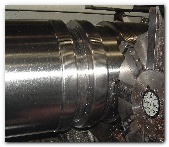

Roll Turning

The Heart of the Steel Plant – the Rolls!

Flat rolls, grooved rolls or custom cuts, if the rolls aren’t to spec, the final product won’t be either.

Not only do bad rolls produce bad products, they can be dangerous to your facility.

A Pioneer in CNC Roll Turning

Riggs was one of the first shops to use CNC lathes to dress passes in rolls.

This is far superior to the old plunge cutting method. CNC pass cutting gives exacting tolerances and an exceptional finish.

Roll Dressing

Work roll turning, with or without the chocks. Another convenience Riggs offers. Local pickup and delivery is also available.

Coal and Coke Facility Repairs

Rebuilds and Overhauls

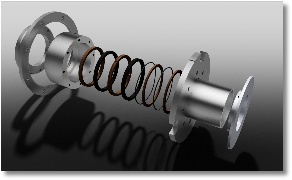

After years of hard service your equipment will need an overhaul. Riggs will tear down your worn machinery and rebuild it from the ground up.

Using the newest components and most modern techniques, they might run better than they have in years!

Minimal Downtime – Fast Turnaround

Though coal and coke can be hard on your equipment, Riggs’ employees work even harder to get your machinery back on-line and keeping you operating.

Better Components …

A lot has changed since many of these units went into service.

Many components are just made better than the OEMs. Better springs, rings and gaskets mean more reliable equipment.

How Safe Are Your Work Platforms?

How safe do your employees feel working on your old, outdated platforms? Are they still up to code?

Replace those aging, rusted, dangerous platforms with new solid units from Riggs.

Chutes and Hoppers

Getting Your Materials from Point A to B!

Everyone’s Hoppers and Chutes are a bit unique. They have to fit back in place just right. Getting that fit correct is something we know at Riggs.

A new custom replacement for a worn out unit or a rebuilt will fit like a glove. Access doors, cleanouts and manways back where they need to be.

You’ll be happy you chose Riggs.

Specialty Blinds – Target Blind

Used during testing and turnarounds, the Target Blind is another example of the specialty blinds Riggs custom designs.

There’s a reason companies choose Riggs for their custom blind work. With other places, if it’s not on the shelf, they just can’t help you. That’s not how we work.

This Target Blind is the perfect example of that. From Spectacle Blinds with machined finishes to Double Bleeders with welded valves. “Not on the shelf” is never an excuse at Riggs.

Photo by Steven Bratman / CC by

Cooling Tower Fan Guards

As original steel guards deteriorate and go out of service …

They become dangerous to work on when removing to repair fans, bearings and shafts.

These new aluminum replacements designed by Riggs Machine are lighter and easier to handle (especially for the size!)

This means unit maintenance is faster, safer and more cost effective.